Valvetrains markings: What do they mean?

Valve timing is a mechanism using valves to control the flow of working gases (air, fuel, exhaust gases) through a piston combustion engine. This is the most common type of mechanical distribution, used mainly in four-stroke internal combustion engines.

The opening of the valves is controlled by the respective cam of the camshaft, which is driven by the crankshaft. In four-stroke engines, the camshaft rotates 2x slower than the crankshaft, because one working cycle of the engine takes two revolutions of the crankshaft.

Inhaltsverzeichnis

The movement of the cam is transmitted to the valves, depending on the type of distribution, by tappets, and lifting rods. If the camshaft turns, the cam starts to run on the valve tappet, which pushes the valve spring, and thanks to this, the valve starts to open.

Engine valve: What is its function?

However, the valve is closed if the cam does not touch the tappet. According to the location of the camshaft and the valve, the valve systems are thus divided into:

1. Timing with a camshaft in the engine block

- F - distribution with one valve on the side of the cylinder and the other in the cylinder head (an obsolete design that is no longer used)

- SV (Side Valve) - with a valve on the side of the cylinder (an obsolete design that is no longer used)

- OHV (Overhead Valve) - with all valves in the cylinder head

2. Timing with a camshaft in the cylinder head

- OHC (OverHead Camshaft) - with valves and camshaft located in the cylinder head

- SOHC (Single OverHead Camshaft) - also referred to as OHC, is a design with valves and one camshaft in the cylinder head

- DOHC (Dual OverHead Camshaft ) - construction with valves and two camshafts in the cylinder head

Today, two-valve control systems are mainly used to control the valve train, namely OHV, and OHC.

OHV (Overhead Valve):

OHV is a type of valvetrain of a reciprocating internal combustion engine. The valves are in the cylinder head, and the camshaft is in the engine block.

With this type of distribution, there is a relatively large distance between the camshaft and the valves. In the case of OHV distribution, the valves are therefore operated using metal lifters, lifting rods, rockers, and cams from below.

Thus, compared to other types of distribution, the OHV valve distribution contains many components that adversely affect the entire unit, manifested by large inertial forces. On the other hand, the advantage of this type of distribution is the simple design solution of the camshaft drive.

Due to the convenient location of the camshaft close to the crankshaft, the distribution drive can be implemented with a simple gear wheel. The distribution drive must be designed in such a way as to enable precise adjustment of the relative position of the crankshaft and camshaft, which does not change during engine operation. However, the gear wheel fulfills all this.

Crankshaft: What is it for, and what forces must it withstand?

The OHV distribution is mainly used in four-stroke engines. As I already mentioned, the camshaft rotates 2x slower than the crankshaft. Engines with OHV valve distribution were installed, for example, in Škoda cars, more precisely in models 105, 120, 130, Favorit 135, 136, or Fabia and Octavia.

OHC (Overhead Camshaft):

The OHC valvetrain is a type of piston combustion engine train in which, in addition to the valves, the camshaft is also located in the cylinder head.

Usually, only a rocker arm is inserted between the camshaft(s) and the valve. Thus, The OHC distribution contains a few components, which reduce inertial forces. The disadvantage of this type of distribution is only the more complicated construction of the cylinder head.

Cylinder head: Did you know what is its function?

However, the advantages of OHC valve timing outweigh its disadvantages, which is why this design is currently the most used type of timing for modern piston combustion engines.

The basic concept of this type of distribution is one camshaft per cylinder head. However, there are two cylinder heads for V-shaped engines, so two camshafts are used (one for each head). An engine with an OHC distribution has at least two valves for each cylinder located in a row and above which the camshaft is located.

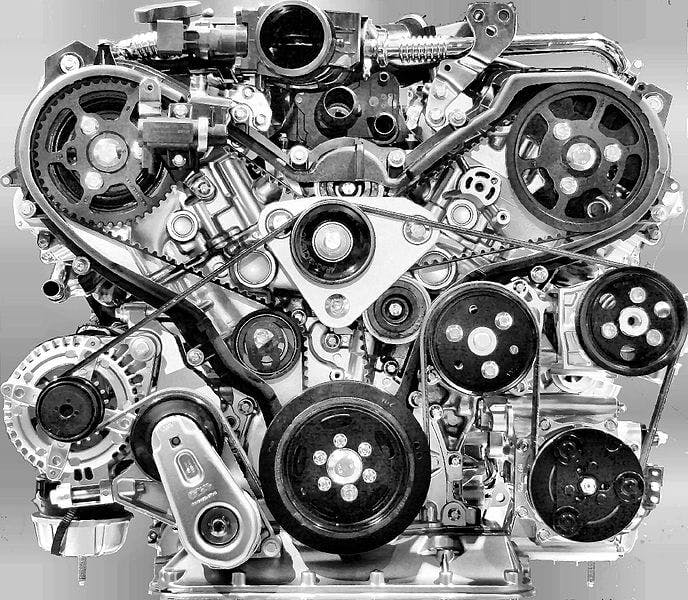

The drive of the OHC distribution can be solved in several ways, either:

- Toothed belt

- Chain

- Toothed gear

As with the previous type of valve train, the drive of the train must be designed in such a way as to enable precise adjustment of the relative position of the crankshaft and camshaft, which does not change during engine operation.

Four-stroke engine: How it works and what are its advantages

Gear drive is very rare, and nowadays, the most common timing drive is a toothed belt or timing chain. As with the previous type of distribution, the OHC distribution is mainly used in four-stroke engines, which means that the camshaft rotates 2x slower than the crankshaft.

SOHC (Single Overhead Camshaft):

SOHC indicates one camshaft per cylinder head. So it is the same type of distribution as the OHC distribution.

Most engines of the type use the SOHC valve train:

- 4-cylinder engine, eight valves

- 3-cylinder engine, six valves

DOHC (Dual Overhead Camshaft):

DOHC refers to a type of valve train in which two camshafts are located in one cylinder head. This type of valve train is used for larger valves per cylinder (3, 4, 5, 6, and so on). The DOHC distribution is also sometimes referred to as 2xOHC.

DOHC valve timing is the most used type of timing today and is used, for example, in the concept of engines such as:

- 4-cylinder engine, 12 valves - 2 intake valves and one exhaust

- 4-cylinder engine, 16 valves - 2 intake valves and two exhaust

- 4-cylinder engine, 20 valves - 3 intake valves and two exhaust

- 4-cylinder engine, 24 valves - 3 intake valves and three exhaust

- 3-cylinder engine, 12 valves - 2 intake valves and two exhaust