Engine valve: What is its function?

The internal combustion engine valve is an important part of the valve train in a reciprocating internal combustion engine.

In this article, we will briefly look at the function of the valve of an internal combustion engine and what stresses it.

Spis treści

How does an engine valve work?

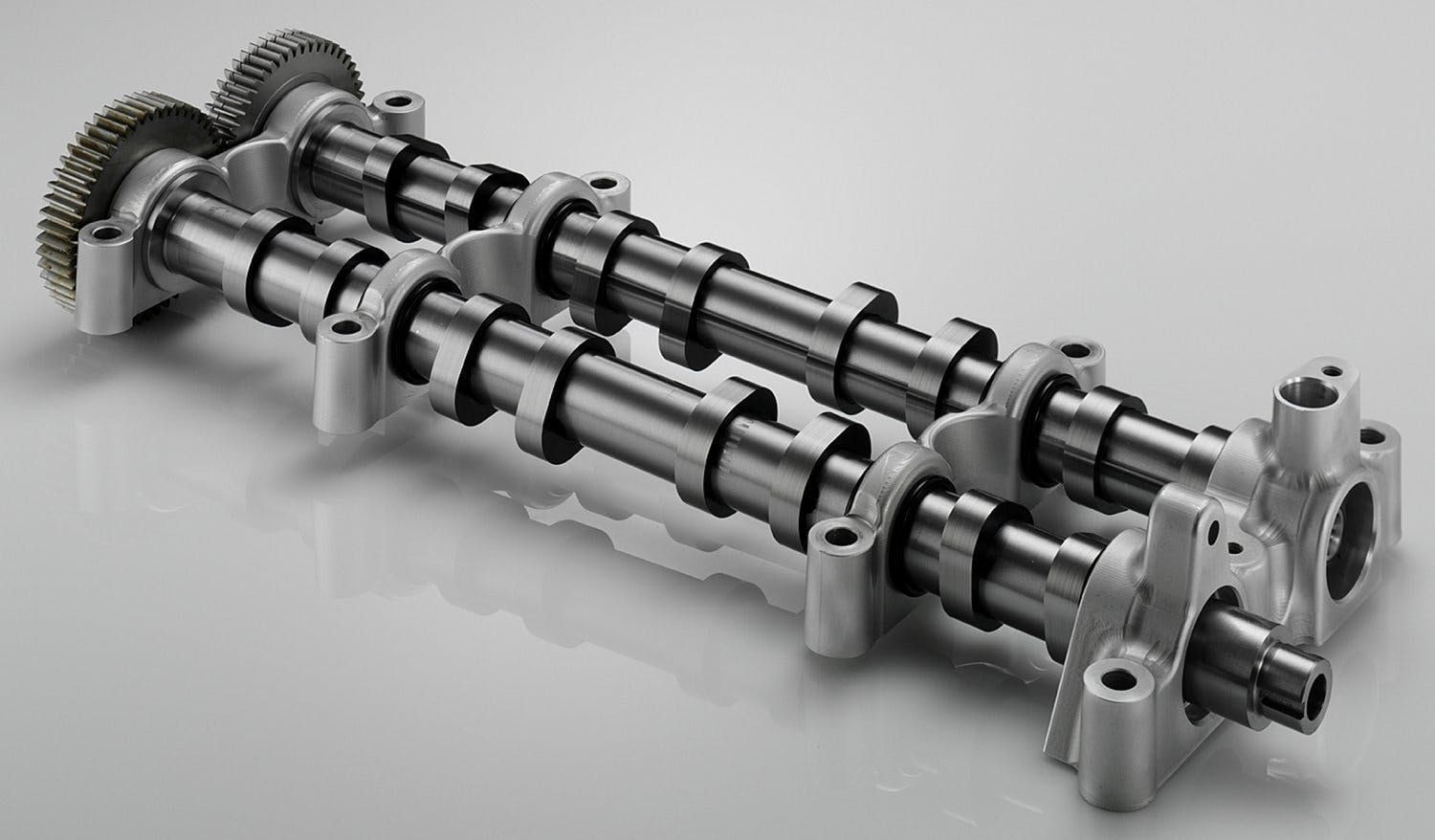

The camshaft controls the valves. If the camshaft rotates, the cam starts to run against the valve tappet, thereby pressing the valve spring, and thanks to this, the valve starts to open. However, the valve is closed if the cam does not touch the tappet.

Camshaft: How it works, and what you didn't know about it?

The valve head thus sits on the valve seat, thus closing the combustion chamber. When the valve opens, its head again extends into the combustion chamber. There are at least two valves for each cylinder of a piston combustion engine, one intake and the other exhaust.

Most of today's modern engines have more valves, most often four valves per cylinder, two of which are intake and two exhaust. Some engines have an odd number of valves per cylinder. One is the well-known 1.8T 20v engine, which has three intake valves and two exhaust valves.

Engine valve construction

An engine valve consists of a head and a stem. The valve head is the widest part of the valve, forming a plate. The valve stem is a narrowed part that resembles a nail without a head. The head of the intake valves is usually larger than that of the exhaust valves, or in the case of an odd number of valves, the number of intake valves is higher than the number of exhaust valves.

The priority is to ensure sufficient filling of the cylinder. Therefore, the size of the intake valves is maximized at the expense of the exhaust valves. The exhaust gas pressure in the cylinder is sufficient at the time the exhaust valve opens to ensure proper cylinder emptying.

The valve stem should be as short as possible so that the weight of the valve does not increase unnecessarily, and it is also the place through which the heat from the valve is removed. The stem is one of the two places through which heat removal from the valve is ensured, and therefore its diameter can be up to 30% of the diameter of the valve seat.

Engine Power And Torque: Which of these parameters is more important?

The bevel angle of the valve bearing surface of the combustion engine is most often 45°. At this angle, good tightness is achieved. However, some engines have intake valves with a bevel angle of the landing surface of 30°. A smaller bevel angle of the valve bearing surface improves the filling of the cylinder and, thus, the engine's performance.

What must an engine valve withstand?

The engine valve is extremely stressed, mechanically and thermally.

- Mechanically, the valve is stressed by the pressure of the flue gas in the combustion chamber, inertial forces, and friction.

- Thermally, the valve is stressed by the high temperature in the combustion chamber.

The thermal load is uneven, which causes thermal stresses. Uneven thermal load affects some requirements placed on the design of the valves. Other requirements that affect the design of the valves result from the design of the combustion engine.

Very high temperatures stress engine valves and the valve seat or valve stem is used to dissipate this heat. For better heat transfer from the valve head to the stem, the cavity inside the valve is filled with a material, most often sodium, which is liquid at working temperature.

However, the cavity is only partially filled, ensuring that when the valve moves, the internal space is washed and, thus, a better transfer of heat from the valve head to its stem.

For larger valves, the valve head can also be hollow. Exhaust valves are thermally stressed much more than intake valves, so they are made of higher quality and more durable materials.