Turbo Lag: What is it, and how to reduce it?

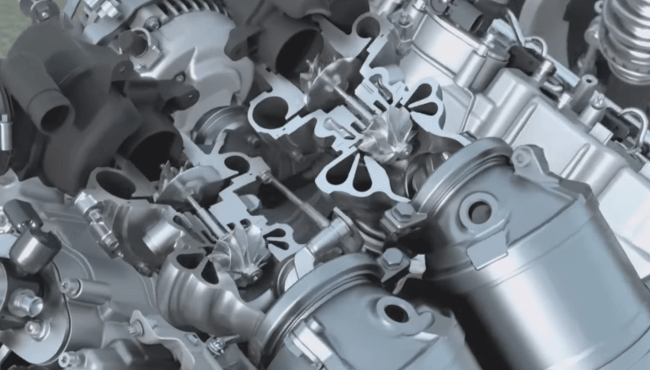

Turbochargers are popular for boosting an engine's power without increasing size or weight. Turbocharged engines are replacing naturally aspirated ones since even smaller engines are able to put out more horsepower and torque.

However, putting the increased power and other benefits aside, turbocharged engines are often associated with the word turbo lag.

Inhoudsopgave

Turbo Lag Meaning

Turbo lag is the delay between the moment you press the accelerator pedal and the moment the turbocharger begins to provide additional power to the engine. This is the time it takes for the exhaust system and the turbocharger to create the required boost to increase power.

The delay can be frustrating, as it makes the car feel sluggish or unresponsive until the turbocharger kicks in. Several factors can contribute to turbo lag, including the turbocharger size, the intake and exhaust systems, and the engine's characteristics.

Turbocharger: What are its advantages, and what is turbo lag?

In general, larger turbochargers will produce more power but also bigger turbo lag because they require more exhaust gas flow to spin up to speed. On the other hand, superchargers do not have this problem since they are driven mechanically via a belt attached to the crankshaft.

How To Reduce Turbo Lag?

We can combat turbo lag in several ways, such as by reducing the inertia of the turbine, for example, by reducing its weight or using bearings with less friction. Let's look at five components, some of which are different types of turbos that reduce turbo lag.

1. Smaller Turbocharger

A smaller turbo will spin up sooner because it needs much less energy from the exhaust than a larger turbo. The problem with a small turbocharger is that it cannot push the same amount of air into the engine as a larger turbocharger at the same rpm.

This problem is solved by increasing the speed of the turbocharger, although this speed cannot be increased indefinitely. Very high revolutions of the turbo also contribute to its faster wear.

2. Variable-geometry Turbocharger (VGT)

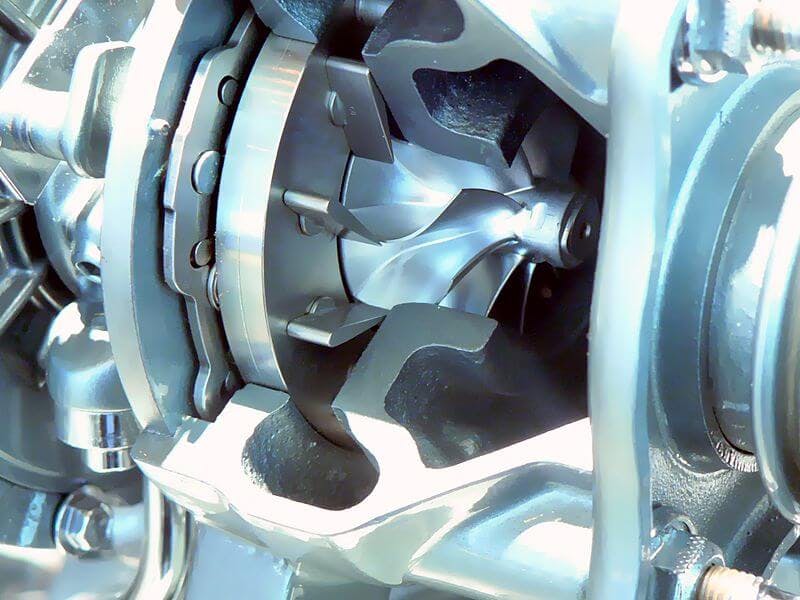

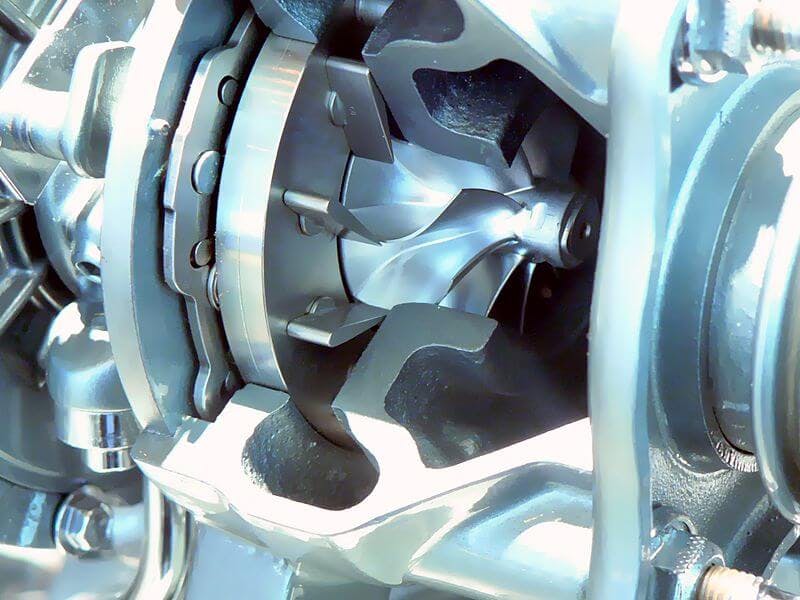

Variable geometry turbochargers use movable vanes to adjust the flow of air into the turbine, thus mimicking an optimally sized turbocharger throughout the power curve.

Variable-geometry turbocharger (VGT): How does it work?

The result is a turbocharger with no observable turbo lag.

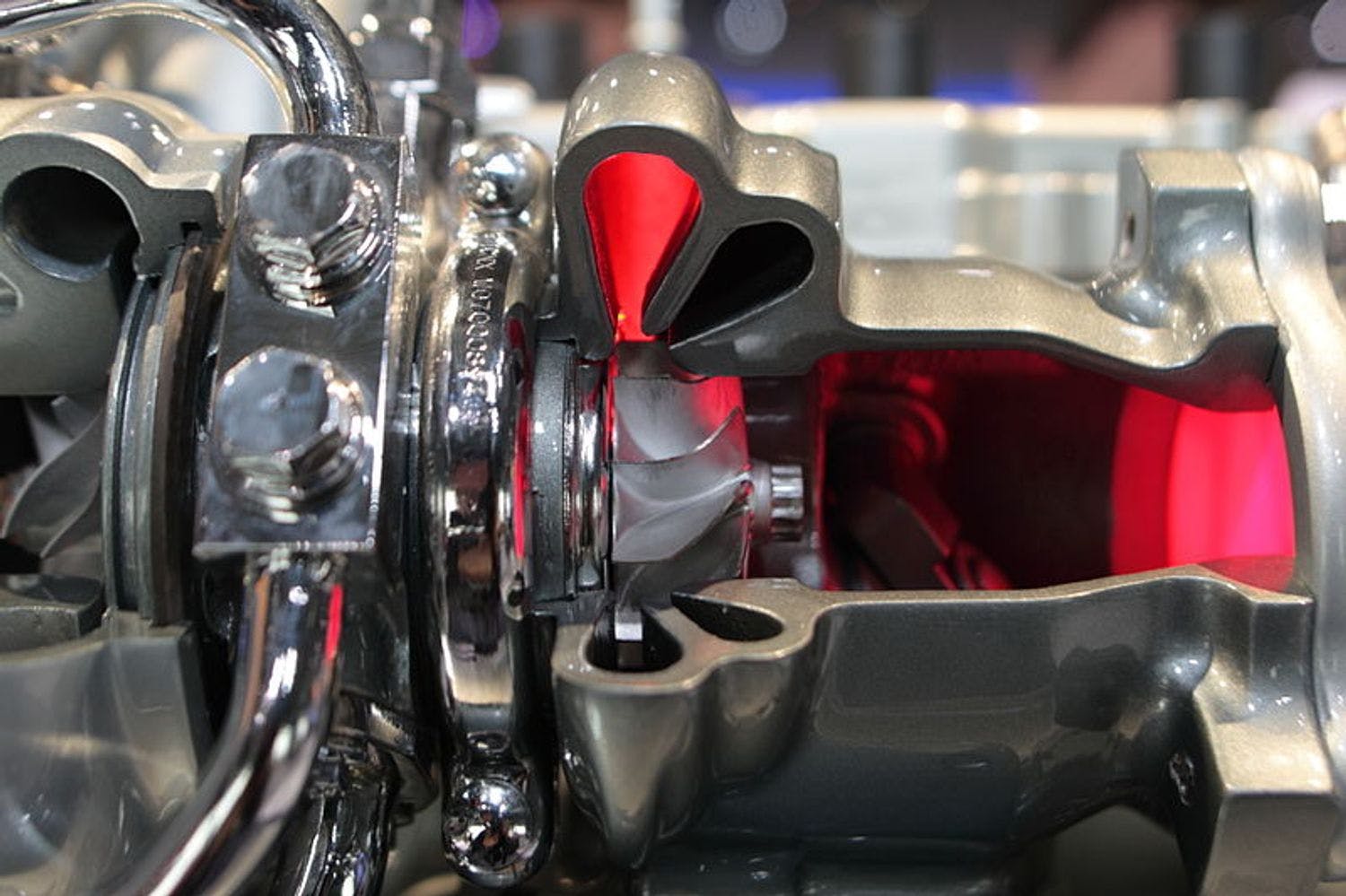

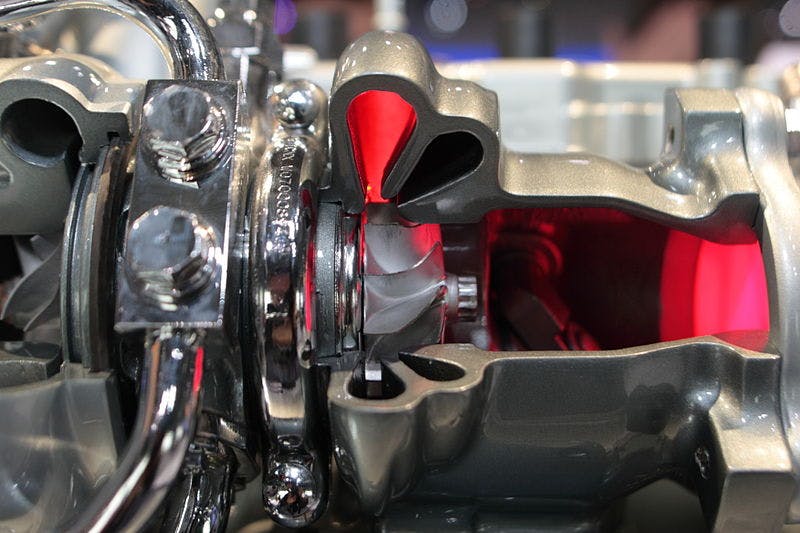

3. Twin-scroll Turbo

This type of turbocharger has two channels for the intake of exhaust gases in the turbine part. Leads lead to each of these channels so that the vacuum does not sap energy from the exhaust gas while one cylinder's exhaust valve has not yet closed while its intake valve has already begun to open. If the ignition in the cylinders is in the order 1-3-4-2, the leads from cylinders 1 and 4 will lead to one channel, and the leads from cylinders 2 and 3 to the other channel.

Twin-scroll turbo: What are its pros and cons?

In this case, there will be no loss of exhaust gas energy because cylinder 3, which would take energy from the exhaust gas from cylinder 1, is not connected to the same pipe. The twin-scroll turbocharger has almost no turbo lag.

The disadvantage of the twin-scroll turbocharger is its difficulty, but also the fact that it is necessary to have an even number of cylinders so that the exhaust gases from the same number of cylinders flow into each channel.

4. Sequential Twin-turbo

Twin-turbo is basically two turbochargers working in parallel or sequentially. In a sequential configuration, one smaller turbocharger runs at low rpm, and the other larger one is turned on at a higher predetermined engine rpm.

Twin-turbo: What are its pros and cons?

Sequential turbos reduce turbo lag but require complex pipes to feed both turbos.

5. Blowoff Valve

The blowoff valve relieves the pressure in turbocharged engines by releasing the compressed air into the atmosphere. The task of the blowoff valve is to prevent the formation of high pressure in the space between the turbocharger and the throttle valve.

Blowoff valve: What is the purpose of this device?

The blowoff valve also reduces turbo lag. Without a blowoff valve, the built-up pressure reduces the speed of the turbine, which means that when the accelerator pedal is subsequently stepped on, the turbo takes longer to spin back up to the speed it left off when the accelerator pedal was stepped on.

Conclusion

We hope you now have an overview of turbo lag and why various turbos exist to eliminate it. Some drivers might confuse turbo lag with low engine speed in the case of a manual transmission. If the engine speed is deficient, waiting for acceleration may take several seconds. However, this wait is not turbo lag but just a wrong gear selection.