Turbocharger: What are its advantages, and what is turbo lag?

A turbocharger, or "turbo" in short, is a device that increases the power of an internal combustion engine by forcing air into the combustion chamber.

The increase in power comes from the engine receiving many more oxygen molecules from the same air volume. Since the air is pressurized, the mixture is more explosive, the engine thus accelerates more easily, and it does not need more fuel.

Inhoudsopgave

- What is the difference between a turbocharger and a supercharger?

- What is turbo lag?

- Low engine revs are NOT turbo lag

- Will a bigger turbo add more power?

- Bi-turbo, Twin-turbo

- Twin-scroll turbocharger

- Variable Geometry Turbocharger

- What is Wastegate for?

- What is the Blowoff valve for?

- So why turbocharge engines?

In addition to the turbocharger, a supercharger or a combination of a turbocharger and a supercharger is also used to supercharge the engine.

What is the difference between a turbocharger and a supercharger?

The key difference between a turbocharger and a supercharger is that a supercharger is driven mechanically via a belt attached to the crankshaft, while exhaust gases from the engine drive a turbocharger.

Since the supercharger uses energy from the engine for its drive, it will take some of the engine's energy, but in the end, it will supply it with more energy. Another disadvantage of the compressor is its lower adiabatic efficiency compared to the turbocharger.

Adiabatic efficiency is the supercharger's ability to compress air without adding excess heat to the air. The lower the air temperature, the denser the air, and it contains more oxygen molecules. So superchargers add more heat to the air than turbochargers, making them less efficient.

As already mentioned, the turbocharger is not driven mechanically but by exhaust gases and therefore does not take energy from the engine, which is more efficient. Compared to the supercharger, however, it has a disadvantage: turbo lag.

What is turbo lag?

Turbo lag is the time between the request for power increase, i.e., pressing the accelerator pedal, and the onset of power (turbo kick-in). In newer models using turbochargers, it may be about 1 second, but it all depends on the turbo type.

In other words, turbo lag is the time it takes for the exhaust system and the turbocharger to create the required boost to increase power. Superchargers do not have this problem because they are driven directly by the engine, and the response to the throttle is, therefore, instant.

Low engine revs are NOT turbo lag

Sometimes low engine revs are mistaken for turbo lag in the case of cars using manual transmission. If the engine speed is low, waiting for acceleration may take several seconds after pressing the accelerator pedal. However, this delay is not turbo lag but the wrong gear choice.

Turbochargers rely on the build-up of exhaust gas pressure to drive a turbine (propeller), which cannot be achieved at idle or low engine speeds. When the engine reaches sufficient revolutions, the turbine begins to rotate in such a way as to create a higher intake pressure than the atmospheric one.

The turbocharger aims to improve the engine's volumetric efficiency by increasing the intake air's density, allowing more power per engine cycle.

Will a bigger turbo add more power?

The size and shape of the turbine (it spins up to 300,000 rpm) affect some of the performance characteristics of the turbocharger. The dimensions of the turbine also determine the amount of air that will flow through the system. In general, the larger the turbine, the greater the airflow capacity.

The performance of a turbocharger is closely related to its size. Large turbochargers need more pressure, which causes turbo lag at low speeds. Small turbos spin quickly but may not have the same power at high acceleration.

To effectively combine the advantages of large and small turbochargers, twin turbochargers or turbochargers with variable blade geometry are used.

Bi-turbo, Twin-turbo:

Twin-turbo or Bi-turbo are two turbochargers working in parallel (jointly) or sequentially (separately). In a parallel configuration, one turbocharger is driven by one half and the other by the other half of the exhaust gases from the engine, and both operate simultaneously. Smaller turbos have less turbo lag than larger turbos, so two small turbos are often used.

In a sequential configuration, one smaller turbocharger runs at low rpm, and the other larger one is turned on at a higher predetermined engine rpm. Sequential turbos reduce turbo lag but require complex pipes to feed both turbos.

Twin-scroll turbocharger:

This type of turbocharger has two channels for the intake of exhaust gases in the turbine part. Exhaust pipes lead both Twin-Turbo ports from the cylinders so that the vacuum does not take energy from the exhaust gas of one cylinder. In contrast, the exhaust valve of the other cylinder has not yet closed, but its intake valve has already begun to open.

If the ignition in the cylinders is in the order 1-3-4-2, cylinders 1 and 4 will lead to one channel, and cylinders 2 and 3 will lead to the other channel. In this case, there will be no loss of exhaust gas energy because cylinder 3, which would take energy from the exhaust gas from cylinder 1, is not connected to the same pipe.

The disadvantage of the twin-scroll turbocharger is its difficulty, but also the fact that it is necessary to have an even number of cylinders so that the exhaust gases from the same number of cylinders flow into each channel.

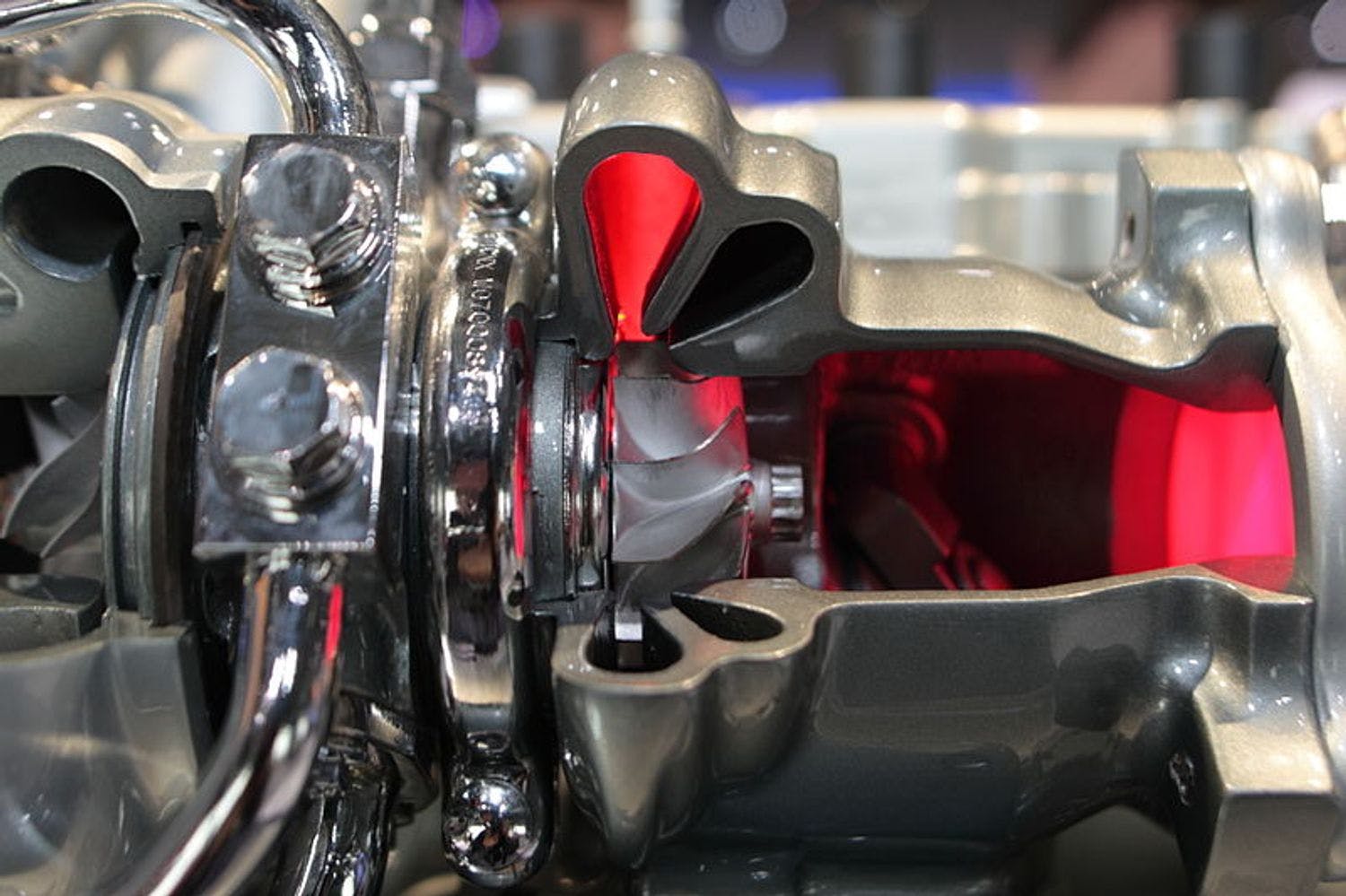

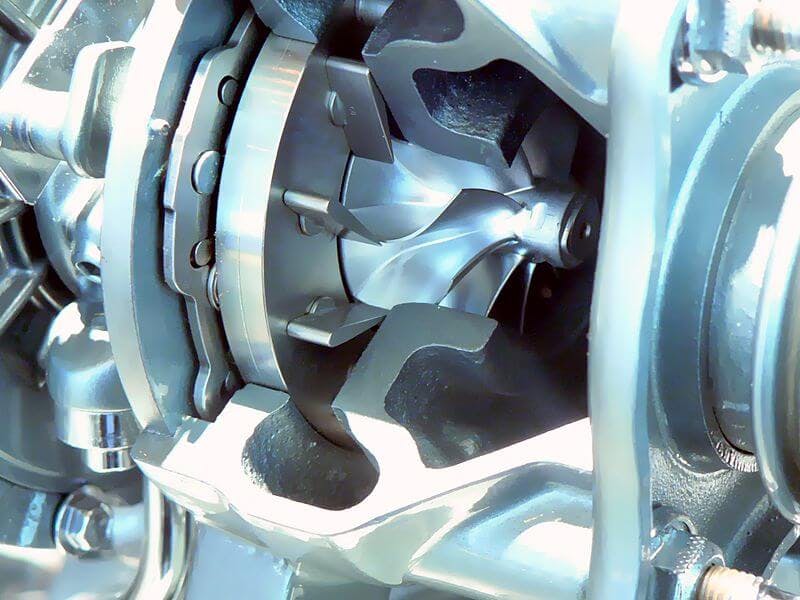

Variable Geometry Turbocharger:

A variable geometry turbocharger uses movable vanes to adjust the airflow into the turbine, mimicking an optimally sized turbocharger throughout the power curve. The result is a turbocharger with no observable turbo lag.

What is Wastegate for?

The wastegate diverts the exhaust gases away from the turbocharger turbine. The speed of the turbine is controlled by diverting the exhaust gases. The main function of the bypass valve is to regulate the filling pressure so as not to damage the engine or turbocharger.

What is the Blowoff valve for?

A blowoff valve is a valve that releases pressure in turbocharged engines. This valve helps empty the space between the turbo and the throttle by releasing compressed air into the environment to reduce wear on the turbo.

When the air is released, a characteristic hissing or whistling sound enters.

So why turbocharge engines?

Turbocharging can increase engine power and reduce fuel consumption, but some manufacturers still prefer large, naturally aspirated gasoline engines. Diesel engines without turbocharging are no longer produced nowadays because they have deficient performance compared to gasoline ones.