Stirling Engine: What are its advantages?

A Stirling engine is a reciprocating heat engine that uses heat from an external source to create energy for the work cycle. This heat is often obtained by external combustion, so it is an external combustion engine.

This type of engine uses chemical energy obtained by burning fuel to heat the working substance, which subsequently performs work in the engine. Combustion always takes place outside the engine, and the working substance is most often gas.

Indholdsfortegnelse

- The history of the Stirling engine in a nutshell

- The construction of the Stirling engine

- How does a single-cylinder Stirling engine work?

- How does a two or more-cylinder Stirling engine work?

- Advantages of the Stirling engine

- Disadvantages of the Stirling engine

- Use of the Stirling engine

- Future innovations

- Interesting facts about the Stirling engine

- Frequently asked questions about the Stirling engine

- Conclusion

The history of the Stirling engine in a nutshell

The development of the Stirling engine began at the beginning of the 19th century when the Scottish engineer and clergyman Robert Stirling tried to create a safer alternative to steam engines, which were notorious for exploding. The Stirling engine was patented in 1816. In the following years, it underwent several improvements to increase efficiency. The Stirling brothers also patented a hot air engine in 1827.

During the 19th and 20th centuries, Stirling engines experienced increased interest and innovation, particularly during fuel shortages or periods of rapid technological progress. Nowadays, Stirling engines are once again coming to the fore as an ecological alternative to traditional combustion engines.

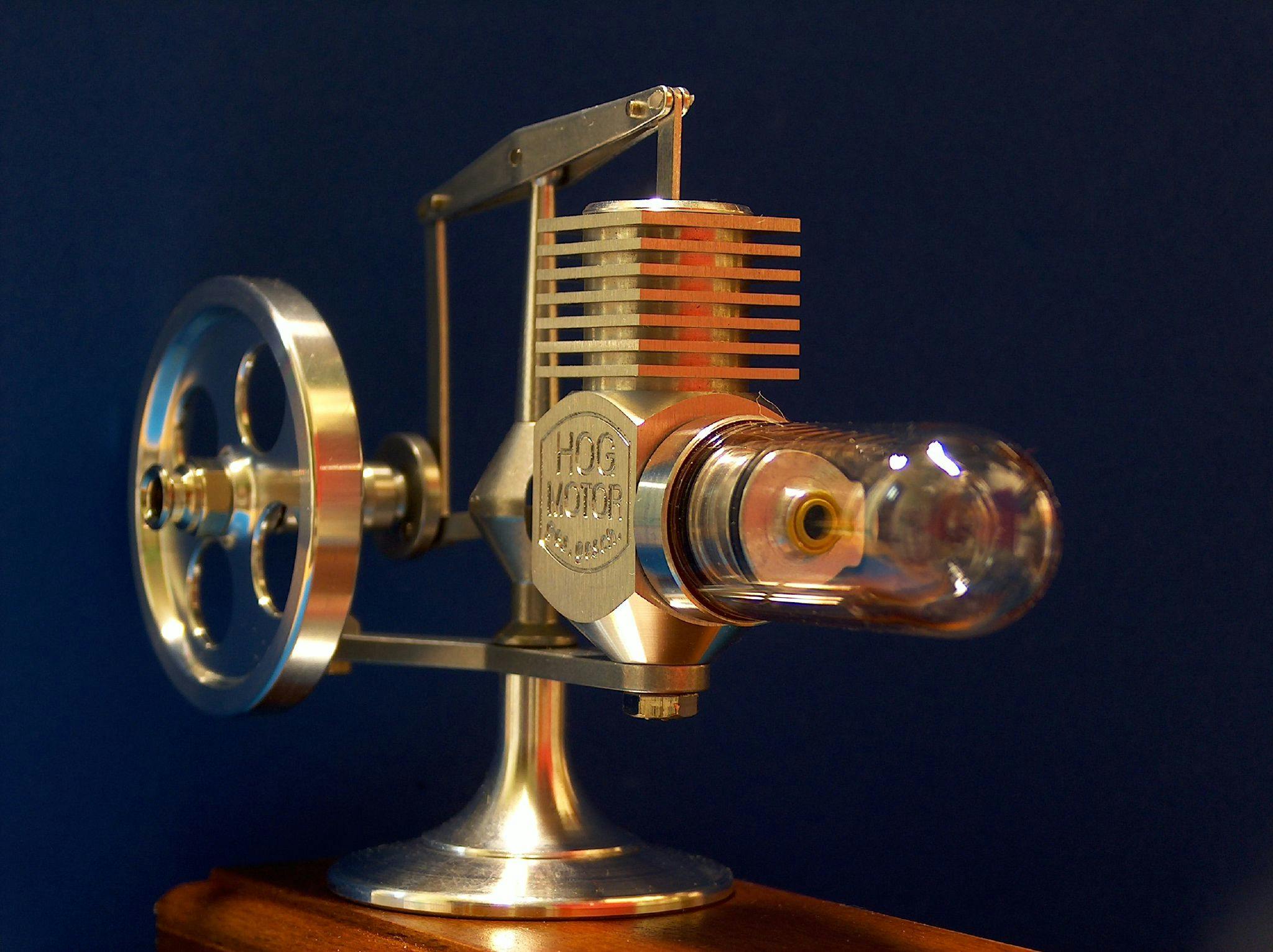

The construction of the Stirling engine

In terms of design, the Stirling engine has many advantages over other combustion engines. The motor is robust and has a simple construction, which makes it very reliable.

This motor is encapsulated and tight, which allows it to be used, for example, underwater or in a vacuum. Since the fuel does not burn inside the engine, there is no unnecessary noise or vibration.

The engine is, therefore, quieter, more refined, and has a longer service life than classic internal combustion engines because its parts are less stressed. The efficiency of the Stirling engine is the same, sometimes even higher, than the best diesel engines. However, its biggest advantage is that different types of fuel can be used to drive the engine.

How does a single-cylinder Stirling engine work?

Initially, the gas is at a low temperature, and thus the pressure is located between the lower (leak) and upper working (tight) pistons, which are interconnected. The lower piston moves to the upper part of the cylinder and expels the gas, which flows around the piston into the lower part of the cylinder, which is heated by an external heat source.

Thanks to the heating, the temperature of the gas inside the cylinder increases. The gas thus increases its volume and pressure and expands upwards while it again flows around the leaky piston.

Engine Pistons: How do they work?

At the top of the cylinder, the gas is cooled, reducing its volume and pressure, which causes the working piston to travel downwards, lifting the leaking piston upwards and allowing the gas to return to the bottom of the cylinder, which is heated. This cycle keeps repeating itself.

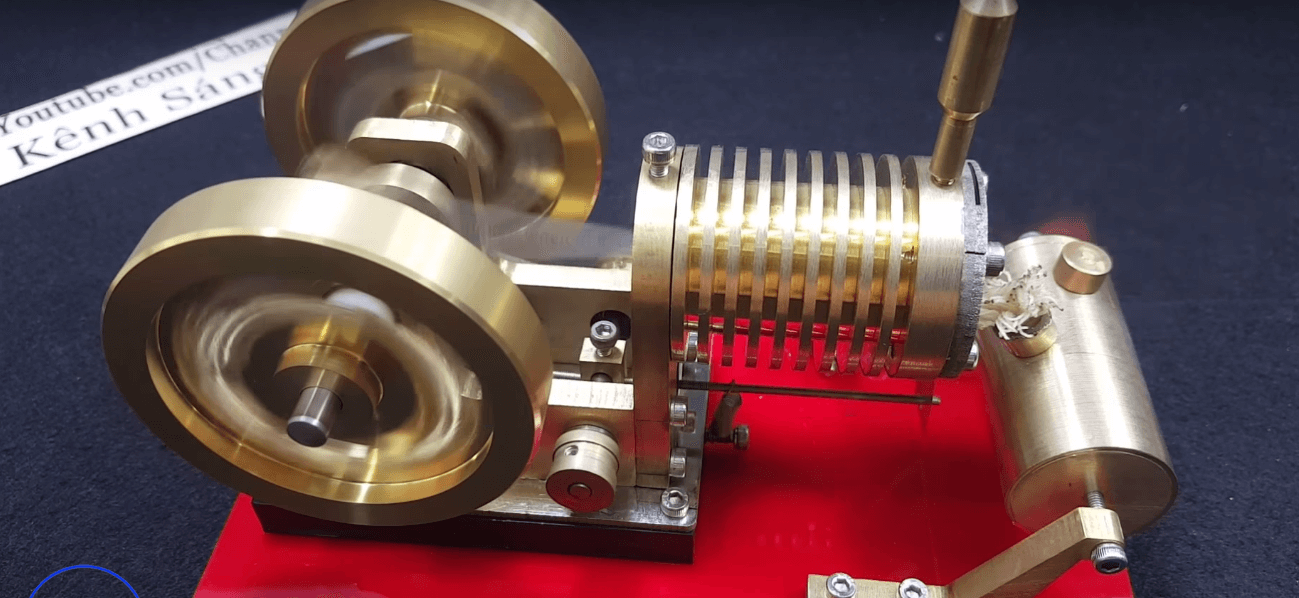

How does a two or more-cylinder Stirling engine work?

An external heat source heats the red cylinder. The gas in the cylinder increases its volume and pressure, pushing the (red) cylinder piston to the top. After the piston reaches the upper limit of the cylinder, the gas flows through the tube into the second (blue) cylinder.

There it is cooled, thanks to which reduces its volume and pressure, which causes the piston to fall, which pushes the cooled gas back into the heated cylinder.

Advantages of the Stirling engine

The Stirling engine has a versatile use and comparable efficiency to spark or diesel engines. As mentioned, it is an engine with external combustion, which creates fewer harmful substances.

Petrol and Diesel Engine: How do they differ?

Since no substance enters or leaves the engine, using the most suitable filling in the cylinders is possible. The main advantages of the Stirling engine include the following:

- Fuel Versatility: Stirling engines can run on virtually any heat source, making them adaptable to a wide range of fuels, including renewable energy sources such as solar energy.

- High efficiency: Thanks to the regenerator and isothermal processes, Stirling engines can achieve higher thermal efficiency compared to combustion engines.

- Low Emissions: The external combustion process results in lower emissions and less pollution, making Stirling engines an environmentally friendly solution. Fewer harmful substances enter the air due to the absence of oil in the fuel.

- Quiet operation: Stirling engines work with minimal noise and vibration because there is no internal combustion and no rapid exhaust gas removal.

Fuels for the Stirling engine

As already mentioned, a huge advantage of the Stirling engine over other combustion engines is that a wide range of different fuels can be used to power the engine, such as:

- Natural gas (it achieves the best results from an economic but also an ecological point of view)

- Liquid and gaseous fuels

- Solid fuel

- Biomass (wood chips, plant residues, and others...)

- Biogas (gas from landfills, sewage treatment plants, coke gas)

- Solar energy

- many more...

Apart from the Stirling engine, no other engine can use such a wide group of different sources for its propulsion.

Disadvantages of the Stirling engine

Like any other device, the Stirling engine has pros and cons. We can include the following among the disadvantages of this engine:

- Lower power-to-weight ratio: Compared to combustion engines, Stirling engines have a lower power-to-weight ratio.

- Complex design: Stirling engines have a more complex design, which leads to higher production costs and more troublesome maintenance.

- The complexity of materials: Efficient heat transfer between the hot and cold chamber is essential for optimal performance. Therefore, the requirements for sealing materials are high, and thus the production costs.

Use of the Stirling engine

The Stirling engine is used in a wide range of applications due to its versatility and unique properties:

- Power generation: The Stirling engine can generate electricity in remote areas using waste heat or renewable energy sources such as solar energy.

- Cogeneration: In combined heat and power (CHP) systems, a Stirling engine can recover waste heat from industrial processes or buildings, increasing energy efficiency.

- Marine propulsion: The Stirling engine is used in submarines and other naval vessels for quiet operation and fuel economy.

- Spacecraft power: Radioisotope Stirling generators are used as a power source for missions in space, such as the NASA Advanced Radioisotope Stirling Generator (ASRG).

Future innovations

Stirling engines are poised to play a significant role in the transition to cleaner and more efficient energy solutions. Potential areas for future innovation include:

- Solar Power: Concentrated solar power systems can use Stirling engines to convert sunlight into electricity, offering a renewable resource.

- Recovery of waste heat: The development of advanced materials and designs can further improve the efficiency of Stirling engines, making them an attractive option for the recovery of waste heat and energy savings.

- Automotive use: Although not yet widespread, the integration of Stirling engines into hybrid vehicle systems could help reduce fuel consumption and emissions.

Interesting facts about the Stirling engine

- First patented engine: The Stirling engine was the first patented engine, which received its patent in 1816, even before the internal combustion engine.

- Safety Innovation: The Stirling engine was originally developed as a safer alternative to steam engines prone to explosions due to high-pressure steam.

- Swedish Submarines: The Swedish Navy has been using Stirling engines in its Gotland-class submarines since 1996, taking advantage of the engines' quiet operation and efficiency.

- Philips Electronics: In the 1950s, Philips Electronics developed a range of Stirling engines for use in radios and other small appliances, helping to popularize the technology.

- Longest-running Stirling engine: The longest continuously running Stirling engine is located at the University of Canterbury in New Zealand. This engine, known as the Canterbury Ringbom, has been in service since 1986.

Frequently asked questions about the Stirling engine

Q: Can a Stirling engine be used in a car?

Answer: The Stirling engine is not yet widespread for automotive use due to its lower power-to-weight ratio and complexity. However, it can be integrated into hybrid vehicle systems to improve fuel efficiency and reduce emissions.

Question: How does the efficiency of a Stirling engine compare to that of an internal combustion engine?

Answer: The Stirling engine can achieve higher thermal efficiency compared to internal combustion engines, often achieving efficiencies of 30-40% or more, while internal combustion engines are typically around 20-25% efficient.

Question: What are the main factors affecting the efficiency of a Stirling engine?

Answer: The efficiency of a Stirling engine depends on several factors, including the temperature difference between the hot and cold chambers, the design of the regenerator, the working gas, and mechanical losses in the engine.

Q: How does a Stirling engine start?

Answer: A Stirling engine requires an external heat source to start operation. Once the working gas heats up and begins to expand, the engine will start and continue to run as long as the heat source is maintained.

Q: What working gas is used in a Stirling engine?

Answer: The working gas in a Stirling engine can vary depending on the specific design and application. Commonly used gases include air, hydrogen, helium, and nitrogen.

Conclusion

The Stirling engine offers a unique combination of fuel versatility, high efficiency, and low emissions, making it possible for a wide range of applications. As technology advances, the potential of the Stirling engine will increase, as will its use in various fields.