Head Gasket: What is it, and how to tell if it's blown?

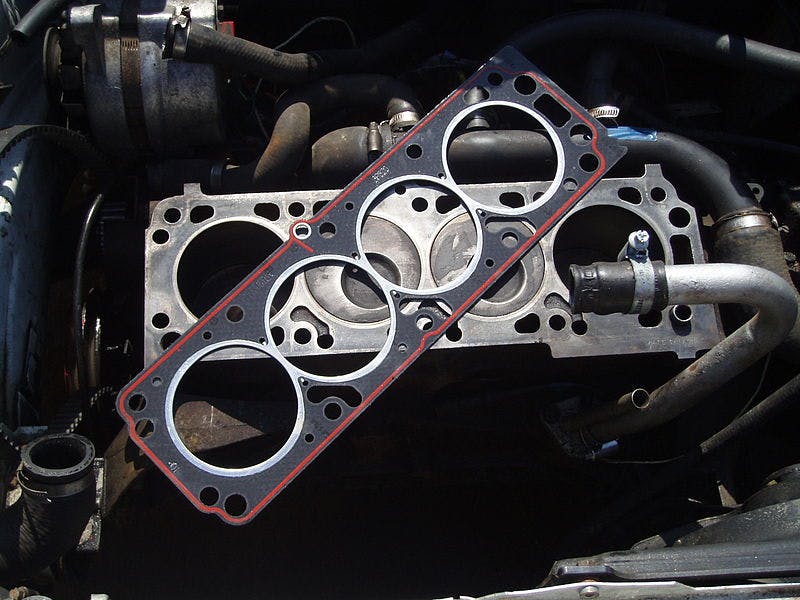

A head gasket is critical in the internal combustion engine, sealing the juncture between the engine block and the cylinder head.

Its primary function is maintaining the separation of the combustion chamber, coolant, and engine oil and ensuring each operates optimally without contamination.

Indholdsfortegnelse

The Role of Head Gasket

Head gasket performs several crucial functions, including:

Sealing Combustion Chambers: The head gasket maintains a tight seal between the engine block and cylinder head, preventing combustion gases from escaping and ensuring maximum compression for optimal engine performance.

Preventing Leakage: The head gasket prevents the leakage of coolant and oil into the combustion chamber, which could lead to engine damage or failure.

Maintaining Pressure: It helps maintain the necessary pressure within the cooling system and oil passages, ensuring proper lubrication and temperature regulation.

Types of Head Gaskets

Head gaskets are manufactured using a variety of materials, each with specific properties that cater to diverse engine configurations and requirements. The most common materials include:

Composite: These gaskets are made of a combination of materials, such as asbestos, graphite, or Kevlar, bonded to a steel core. Composite head gaskets are generally more flexible and offer better sealing.

Multi-Layer Steel (MLS): MLS head gaskets consist of multiple layers of embossed steel coated with a thin layer of elastomeric material. They are highly resistant to heat and pressure, making them suitable for high-performance engines.

Copper: Known for their excellent thermal conductivity and malleability, copper head gaskets create a reliable seal, even in engines with uneven surfaces. They are typically used in racing or high-performance applications.

Elastomeric: This gasket contains a steel core with molded rubber sealing beads. Elastomeric head gaskets provide excellent sealing and are used predominantly in performance engines.

Signs of a Blown Head Gasket

Recognizing the symptoms of a blown head gasket is crucial for timely intervention and repair. Key indicators include:

Engine Overheating

Coolant Contamination

White Smoke

Bubbles in the Radiator

Loss of Power

1. Engine Overheating

A damaged head gasket can cause coolant leakage, resulting in engine overheating. The coolant leakage does not manifest as a puddle under the car, so you must rely on the coolant temperature, coolant warning light, or regular inspection.

Red Engine Coolant Light: Stop your car now! 🚨

2. Coolant Contamination

Coolant mixed with engine oil appears milky and frothy, which can be observed on the oil dipstick or filler cap.

Coolant Liquid: What do the different colors mean?

3. White Smoke

White, sweet-smelling smoke from the exhaust may indicate coolant leaking into the combustion chamber.

4. Bubbles in the Radiator

Bubbles in the radiator or coolant overflow tank are signs of combustion gases entering the cooling system.

5. Loss of Power

A compromised combustion chamber can lead to reduced engine power and poor performance.

Repairing and Replacing Head Gaskets

Replacing a head gasket is a complex and labor-intensive process. The steps typically include the following:

Drain Coolant and Oil: Drain the engine coolant and oil to prevent contamination during the repair process.

Remove Components: Remove the necessary components, such as the intake manifold, exhaust manifold, and timing belt, to access the cylinder head.

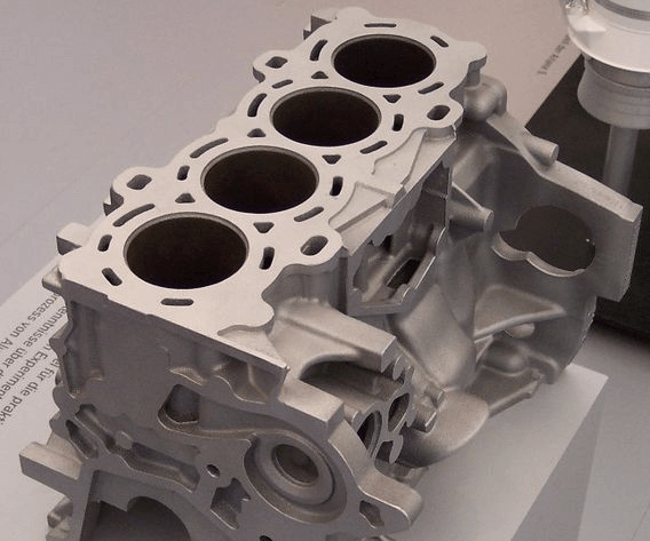

Remove Cylinder Head: Detach the cylinder head from the engine block, inspect it for damage or warping.

Clean Surfaces: Clean the engine block and cylinder head surfaces, ensuring they are free of debris and old gasket material.

Install New Gasket: Position the new head gasket according to the manufacturer's specifications, and carefully place the cylinder head back onto the engine block.

Reassemble Components: Reinstall all removed components, following the manufacturer's torque specifications and guidelines.

Refill Coolant and Oil: Refill the engine with the appropriate coolant and oil, then start the engine and check for any leaks or issues.

Preventing Head Gasket Failure

To minimize the risk of head gasket failure, follow these best practices:

Regular Maintenance: Adhere to the manufacturer's recommended maintenance schedule, including regular coolant and oil changes.

Monitor Engine Temperature: Keep an eye on the engine temperature gauge to detect overheating issues early.

Use Quality Components: Choose high-quality head gaskets and associated components for increased durability and longevity.

Avoid Overloading: Avoid overloading the engine or using low-quality fuel, which can lead to excessive heat and pressure.

Conclusion

A well-functioning head gasket is essential for optimal engine performance. Understanding the various types of head gaskets, recognizing the symptoms of failure, and adhering to proper maintenance practices can help ensure a long-lasting and reliable engine.

Always consult a professional mechanic to accurately diagnose and repair the problem when faced with head gasket issues.