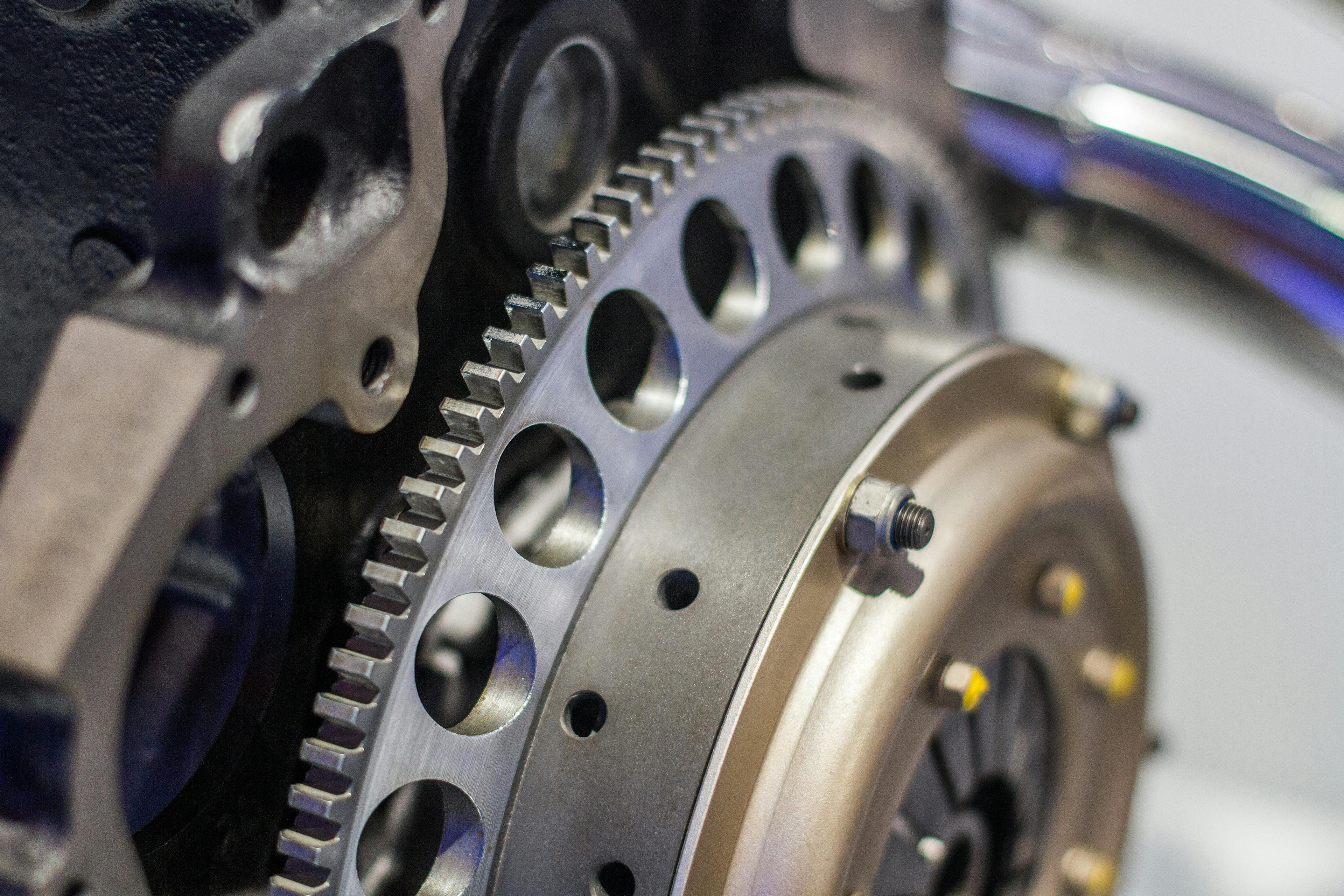

Flywheel: What effect does it have on engine operation?

The flywheel is an essential part of the engine's mechanical system and performs several critical functions. Its purpose is to accumulate and release energy, making it an important part of many industrial and mechanical applications.

In this article, we will shed light on the function of the flywheel, its effect on engine operation, and its lifespan.

Spis treści

How a Flywheel Works

As the engine's pistons move up and down, the crankshaft converts this linear motion into rotational motion. The flywheel stores some of this kinetic energy and releases it when needed to maintain a consistent engine speed.

When the engine's pistons are in the power stroke phase, the flywheel absorbs excess energy to help stabilize the engine. During the non-power stroke phases, the flywheel releases stored energy to keep the crankshaft turning smoothly, maintaining a consistent engine speed.

Crankshaft: What is it for, and what forces must it withstand?

The flywheel and the crankshaft are usually balanced together to prevent them from oscillating at higher engine speeds.

Types of Flywheels

There are two primary types of flywheels used in automotive applications:

Solid flywheels

Dual-mass flywheels

1. Solid Flywheels

Solid flywheels are traditional and consist of a single, solid metal disc. They are durable and can withstand high temperatures, making them suitable for high-performance applications.

2. Dual-Mass Flywheels

Dual-mass flywheels consist of two separate sections connected by springs and dampers. These components absorb vibrations and reduce noise, providing a smoother, quieter driving experience.

Petrol and Diesel Engine: How do they differ?

Dual-mass flywheels are commonly used in modern vehicles, especially diesel or turbocharged gasoline engines.

Key Functions of a Flywheel

Flywheels play several essential roles in an internal combustion engine:

Energy Storage: A flywheel helps maintain consistent engine speed and smooth operation by storing and releasing kinetic energy.

Vibration Reduction: Flywheels reduce vibrations produced by the engine, providing a more comfortable driving experience.

Moment of Inertia: Flywheels have a high moment of inertia, which helps maintain a stable engine speed during rapid acceleration or deceleration.

Transmission Engagement: In manual transmission vehicles, the flywheel provides a friction surface for the clutch to engage and disengage power from the engine to the transmission.

Signs of a Failing Flywheel

A malfunctioning flywheel can cause several issues, including:

Vibrations: Excessive vibrations felt in the vehicle, particularly during acceleration or deceleration, could indicate a damaged flywheel.

Clutch Slipping: A worn flywheel surface can cause the clutch to slip, resulting in poor acceleration and difficulty shifting gears.

Noise: Unusual noises like rattling or grinding may signal damaged or dual-mass flywheel components.

Difficulty Starting: A warped or damaged flywheel can cause starter motor issues, making it difficult to start the engine.The influence of the flywheel on engine operation

Flywheel Lifespan

Each flywheel must be balanced because it is a rotating body that would otherwise cause vibrations while the engine runs. Balancing is carried out on a balancing machine by gradually drilling out the material around the circumference of the flywheel.

The lifespan of the flywheel is usually set for the same period as the lifespan of the entire car. However, it may vary depending on the manufacturer and brand of the car. The driving style is the main factor affecting the flywheel's lifespan.

Flywheel Replacement and Maintenance

Flywheel replacement is typically performed during a clutch replacement, as both components are interconnected and wear over time. During this process, inspect the flywheel for signs of wear, damage, or warping.

If any of these issues are present, replacing the flywheel is necessary to ensure smooth engine operation and transmission engagement. To maintain your flywheel and ensure its long lifespan, follow these tips:

Regular Maintenance: Adhere to your vehicle's maintenance schedule, including timely oil changes and clutch inspections. This will help prevent premature wear on the flywheel and other components.

Smooth Gear Changes: Practice smooth gear changes to reduce stress on the flywheel and clutch system. Avoid aggressive driving or abrupt gear changes, which can cause excessive wear.

Proper Clutch Use: Avoid riding or using the clutch unnecessarily, as this can lead to premature wear on both the clutch and flywheel.

Conclusion

In conclusion, understanding the flywheel's crucial role in your vehicle's engine can help you recognize potential issues and take appropriate steps to maintain its function.

Regular maintenance, proper clutch use, and smooth gear changes are key to ensuring the longevity and efficiency of your flywheel and overall driving experience.